Sam Turbo

Sam Turbo

AR SERIES -

SLURRY PUMPS SINGLE CASING.

Operating range:

- Capacity : Upto 2800m3/hr

- Head : Upto 70m

- Temp : Upto 110*c

- Pressure : Upto 40 bar

- Pump size :DN 50 mm to 350 mm

Application:

- Liquid of abrasive and coarse grained solids

- Lime mid slurry , Milk of lime, liquor upto 50% solids

- Sand water mixtures

Design Features:

- Twin casing / single casing design

- Outer casing in CI / carbon steel

- Heavy duty and single stage

- Inner casing in NI-Hard/HI-Chrome to take entire wear the armored centrifugal pump is designed to suit various slurry applications.

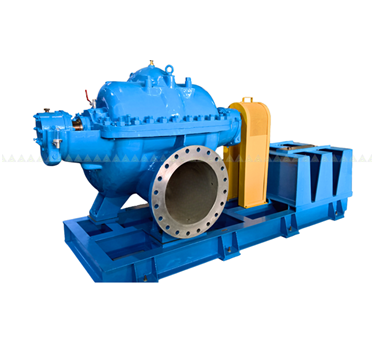

ZM SERIES -

DOUBLE SUCTION SPLIT CASE PUMP

Operating Range:

- Capacity: UPTO 4000 M3/hr

- Head: Upto 140M

- Temperature: Upto 200*C

- Pressure: Upto 40 bar.

- Pump Size: DN 50mm to 700 mm

Application:

- FAN PUMP, STOCK FEED,

- STOCK CIRCULATION

- CENTRI-CLEANER APPLICATION IN PULP & PAPER MILLS

- STROM WATER

- INDUSTRIES TRANSFER WORKS

Design Features:

- SPLIT CASE, SINGLE STAGE

- DOUBLE SUCTION , RADIAL STAGGERED VANE IMPELLER

- HIGH RELIABLITY

- REVERSE ROTAION AVAILABLE.

- VIBRATION FREE PERFORMANCE.

- GLAND PACKING

- MECHNICAL SEAL

- REVERSE ROTATION AVAILABLE

TU SERIES -

SPLIT CASE 2 STAGES

Operating Range:

- Delivery Sixe: 80mm to 200mm

- Capacity: up to 600 m³/hr

- Head: Upto 125m

- Temperature: upto 125° C

- Pressaure: Upto 20 bar

Applications:

- Water, Fire-fighting

- Fan pump, stock feed, stock circulation, centri-cleaner application in pulp & paper mills

- Storm water, irrigation

- Industries transfer works

Design Features:

- Axial split two stage

- Single suction, radial

- Vibration free

- Gland packing/Mech seal

TPS+H SERIES -

MEDIUM CONSISTENCY PUMP

Operating range:

- Capacity : Upto 500m3/hr

- Head : Upto 140 M

- Temperature: Upto 150 *C

- Pressure : Upto 22 Bar

Application:

- Handling Pulp & Paper stock up to 8% -12% Consistency

- Available within built (or) External vacuum pump

Design Features:

- Open impeller with Fluidizer

- Centrifugal & Single stage

- End suction & Top/Horizontal Discharge

- Vibration free casing Mounting to the base frame

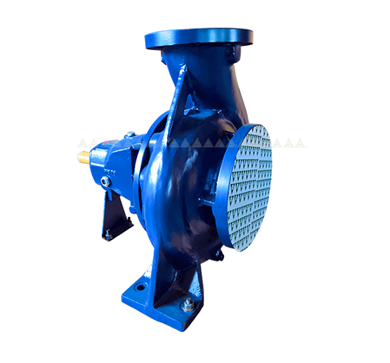

SPS+T SERIES -

HEAVY DUTY PULP & PAPER STOCK PUMP

Operating Range:

- Capacity: Upto 2000m3/hr

- Head: Upto 80 M

- Temperature: Upto 140*C

- Pressure: Upto 22 Bar

- Pump Size : DN 32 to 400 mm

Applications:

- Handling pulp & paper stocks upto 7% Consistency

- All liquor applications suitable

- Suitable for high capacity requirements of acids, alkaline, corrosive slurries ,heavily contaminated liquids , raw sewage & Sludge

Design Features:

- Wide passage in impeller suction zone

- Non- clogging design

- Open impeller with renewable front wear plate & closed impeller with wear ring

- Simple external adjustment to maintain constant clearance between impeller & wear plate

- Gland packed /mechanical seal / dynamic seal tapper roller bearing to talk care of radial thrust loads

TCH+N SERIES -

CHEMICAL PROCESS PUMPS

Operating range:

- Capacity: Upto 700 m3/hr

- Head: Upto 180 M

- Temperature: Upto 200*C

- Pressure: Upto 26 Bar

- Pump size : DN 25mm to 200mm

Application :

- For low Consistency Pulp & stock

- Green liquor, black liquor, caustic and corrosive slurry

- For lime mud slurry, extraction Alkalies , Acids, NaOH ,China clay, Fitrate

- For hypo, spent wash, starch etc.

Design Feature:

- Confirming to ANSI B73.1

- Semi open impeller with Balancing Holes

- End Suction & Top Center line discharge

- Simple external adjustment for impeller wear

- Gland packing / Mechanical seal / dynamic seal

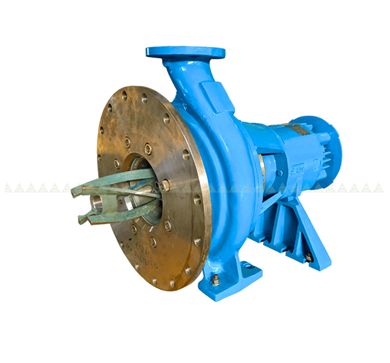

CPC SERIES -

CHEMICAL PROCESS PUMP

Operating Range :

- Capacity :Upto 750M3/hr

- Head : Upto 150 M

- Temperature : Upto 200*C

- Pressure : Upto 22 Bar

- Pump Size :DN 32 to 200 mm

Application:

- For Pulp with less than 1.5% Consistency,

- Fan pump De- inking process liquors , clarified water , back water , white water ,

- For Dewatering, etc.

- For the use of Chemicals , Acids, Alkalis, Dyes, hydrocarbons etc.,

- For DM Water, Hot water, Condensates,

Design Feature:

- Confirm to DIN 24256

- Closed impellers with balancing holes

- Wear ring to maintain the clearance

- Back pull out design

- Gland packing / mechanical seal / only 4 bearing frames to cover 32 models

WP SERIES -

WATER PUMPS

Operating Range:

- Capacities : Up to 550m³ /hr

- Head : Up to 100 m

- Temperatures : Up to 120° C

- Pressure : Up to 16 bar

- Pump Size : DN 32 to 150 mm

Application:

- De-inking water , soft water,

- Centri Clearner Etc,

- Clarified water, back water, white water

- Booster Service

Design Features:

- Conforming to DIN 24255

- Back pull out design

- Gland packed / Mechanical sealed

- Closed impeller Design with wear ring, for close clearance

MD SERIES -

MULTI - STAGE PUMPS

Operating Range:

- Capacity : Up to 350m³ /hr

- Head : Up to 600 m

- Temperature : Up to 120° C

- Pressure : Up to 90 bar

- Pump Size : DN 40 to 150 mm

Applications:

- High pressure application in pulp & paper mills

- Main & auxiliary condensate extraction

- General water

- Dewatering & Descaling

Design Features:

- Multi stage with single suction -closed impeller

- Axial thrust compensated by Balancing Drum or Disc

MF SERIES -

MIXED FLOW PUMPS

Operating Range:

- Capacity: Up to 3000m³ /hr

- Head: Up to 40 m

- Temperature: Up to 110° C

- Pressure: Up to 7.5 bar

- Pump Size: DN 200 to 450 mm

Applications:

- Stock feed

- Stock Circulation / pulp transfer/ Centric cleaner/clear liquid

- Turbid or slightly contaminated liquid

Design Features:

- Horizontal, Single stage

- End suction & discharge branch arranged tangentially upwards / Horizontal

- Open impeller construction

VG SERIES -

VERTICAL CANTILEVER PUMPS

Operating Range:

- Capacity : Up to 400m³ /hr

- Head : Up to 50m

- Temperature : Up to 120° C

- Pressure :Up to 22 bar

- Pump Size : DN 25 to 200 mm

Applications:

- Suitable where space economy matters

- Suitable for Acids, Alkalies & Slurries

- Waste water, sludge handling

Design Features:

- Vertical suspended / single shaft Design/ No intermediate Bush Bearing Support

- Simple Mounting & self-priming

- Up to 2mts Submersion Depth

- Can Be Extended Further with Suction Spool

VO SERIES -

VERTICAL SUMP PUMPS

Operating Range:

- Capacity : Up to 900m³ /hr

- Head : Up to 120 m

- Temperature : Up to 120° C

- Pressure : Up to 22 bar

- Pump Size : DN 25 to 300 mm

Applications:

- Suitable where space economy matters

- Suitable for Acids, Alkalies & Slurries

- Waste water, sludge Handling

- Sludge Handing

Design Features:

- Vertical Suspended with open / closed impellers

- With Intermediate Bush Bearing Support

- Simple mounting and self-priming

- Up to 10 m Submersion Depth

- Simple , Fast , External Impeller Adjustment

Chemical Process Pump (ECH+N)

Operating Range :

- Delivery Size: DN 25 to 200 mm

- Capacity: Up to 700m³ /hr

- Head: Up to 180 m

- Temperature: Up to 200° C

- Pressure: Up to 26 bar

Applications:

- Handles all chemical process requirements

- Acids, alkalies, corrosive slurries

- Suitable for all liquids with / without solids

- Green liquor, black liquor, Caustic Slurry, lime-mud slurry, extraction, Alkalies, Acids, NaOH, China clay, Filtrate, Hypo, Spent wash, starch etc. in pulp, paper mills & basic metal industries

Design Features:

- Conforming to ANSI B73.1

- Open impeller construction

- End suction / Top center line discharge

- Only 3 bearing beds to cover 32 models

- Gland packed / mechanical seal

- Simple external adjustment for impeller wear