Tunnel Ventilation

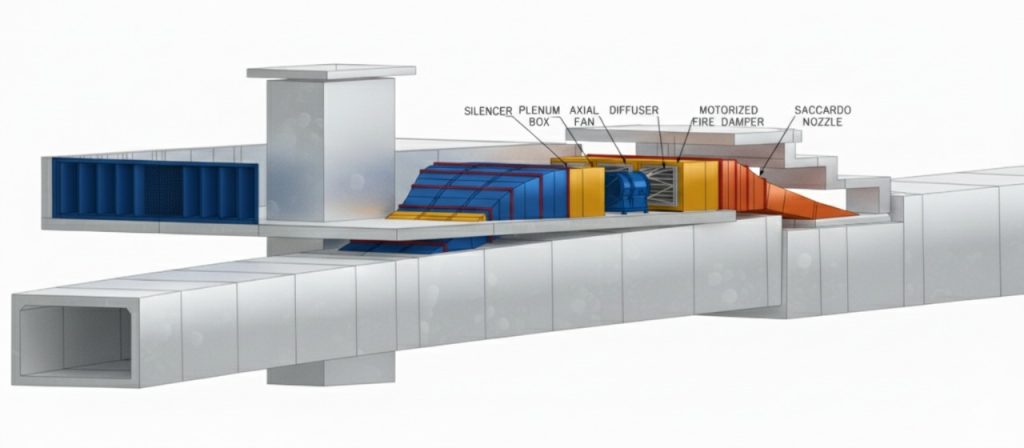

Tunnel ventilation systems are designed to maintain safe air quality both inside and outside the tunnel to meet stringent air quality standards. Ventilation systems work by drawing fresh air from the tunnel entry, which is then pushed through the tunnel by the movement of vehicles and jet fans. Before the tunnel exit, air is pushed up and out of the tunnel through a ventilation system and into the atmosphere where it mixes with fresh air. Research from around the world clearly shows emissions from well-designed tunnel ventilation systems have no measurable effect on local or regional air quality. An internationally recognised air dispersion model is used to assess the design and height of ventilation structures in achieving effective and safe dispersion. The model takes into account existing air quality, local weather and topography and conservative assumptions about vehicle emissions and types. This modelling is based on worst case scenarios to ensure the ventilation system is effective in even the most unlikely circumstances, such as continuously congested Traffic. TAP Engineering has successfully executed the Mumbai Coastal Road Tunnel Project 4 with Saccardo Injector Tunnel Ventilation System.The Mumbai Coastal Road (MCR) is a 4-lane highway that connects the Bandra -Worli Sea Link to Marine Drive. A key element of this route is a twin-bore tunnel with total length of about 3km (a 2km TBM-excavated central section, plus cut-and-cover ramps at both ends). This is the first time in India, the Saccardo Injector Ventilation System was utilised. This MCR Tunnel scope also included 3 axial fans with variable speed drive, SS Nozzle, Automation system for monitoring the Air Flow, Velocity of the tunnel and Cross-Passage Ventilation System for Twin Tunnel (Emergency Condition).